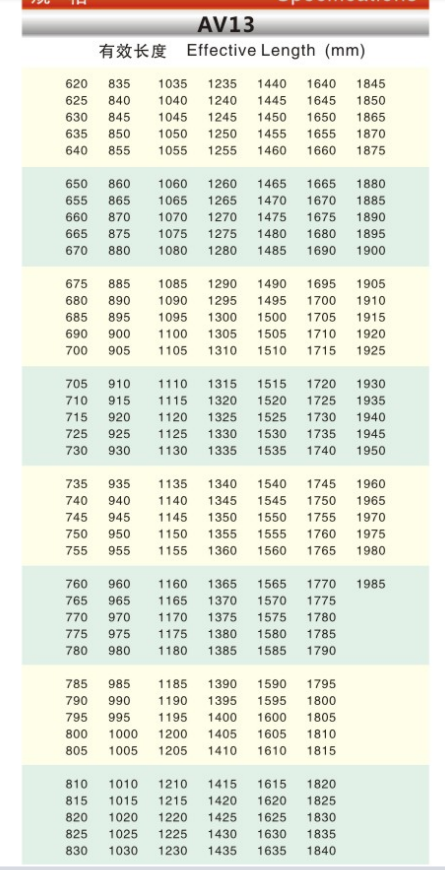

Automotive V Belt AV13

- Transportation:

- Ocean, Air

- Port:

- NINGBO, SHANGHAI

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | ZHEJIANG |

|---|---|

| Payment Type: | T/T,L/C |

| Incoterm: | FOB |

| HS Code: | 4010390000 |

| Transportation: | Ocean,Air |

| Port: | NINGBO,SHANGHAI |

Product Description

Product Description

Automotive V Belt AV13

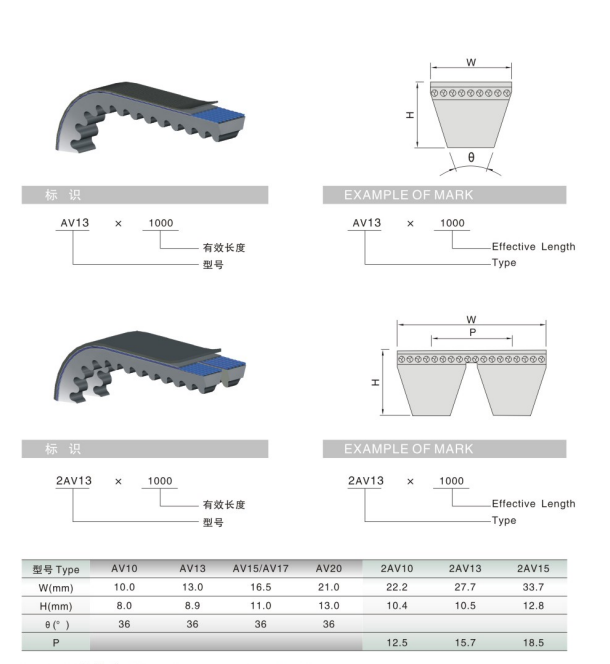

- Characteristics & Advantages

- World-class technology for belt angle control, guarantees the smooth operation.

- Moulded bottom teeth,greatly improved belt flexibility.

- Extraordinary strong polyester tension line,contracts when being heated to deal with stretch.

- Special top fabric,good at heat and oil resistance.

- V-belt

- The transmission structure shall be convenient for the installation and replacement of V-belt.

- In horizontal or near horizontal belt drive, the tight side of the belt should be at the bottom and the loose side should be at the top, which can increase the wrap angle of large and small pulleys.

- When multiple V-belts drive, in order to avoid uneven load distribution of each V-belt, the length of V-belt on the same belt pulley should be matched. All belts must be replaced at the same time.

- Ordinary V-belt and narrow V-belt shall not be mixed in the same transmission device.

- V-belt is usually endless ring belt, in order to facilitate installation, the shaft spacing and preload should be adjusted. For drives without tensioning wheels, the bearing position of one of the shafts should be able to move along the belt length.

Install method of transmission belt

When you replace a belt or install a belt in a new gear,please follow these steps:

- 1. Shutting down the equipment ,loosen the bolts,remove the belt :Turn off the power,remove the protective cover.Loosen the bolts on the pedestal,so that the motor can move back and forth .Move the motor,remove belt from pully.

- 2. Check the old belt and pulleys:Check whether these is abnormal wear on the old belt in order to confirm the maintenance of the gear,check whether there are cracks or breakages in the pulley.If it's worn too much,you must replace the pulley.

- 3. Check other components,align the pullys:Check other components of the gear,such as symmetry,wear and lubrication of the bearings and bushings,to ensure that the pulley grooves parallel to each other.

- 4. Install the new belt :Locate the belt on drive pully,turn the pullys slowly to facilitate installation.

- 5. Check the belt tension:Tighten the gear center distance,hand-turn the driving wheel for a few laps .Check whether the belt tension is appropriate by a tension gauge.Tighten the bolts of the motor with required torque.

- 6. Debugging and adjustment,lubricate correctly:start up the gear,run under full load conditions.Keep observing to see whether any abnormal vibration,noise occurs in the commissioning process.Shut down the equipment after running for some time and heck the heat conditions of bearings and motor.Too hot means too tight tension or bearing asymmetry,or lubrication is not correct.Stop debugging when the belt has completely consistent withe the pully grooves,check and adjust the tension to recommended value.

- Focusing on high quality belts, ACRON devotes itself to supplying global customers with outstanding cost performance belts and perfect after-sales service.Products can be customized according to the requirements and samples.If you have special requirements,please contact us and we will try to satisfy your needs.

Related Keywords

Related Keywords