PET Transparent Aluminum Composite Dielectric Printing Film

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Zhejiang China |

|---|

Product’s property and application :

Our mainly products are PET Film, Decoration Base Film, Hot Stamping Foil Base Film, Release Liner Base Film,Protection Base Film, Electronic Insulation Base Film, BOPET films and so on. We accept customized.

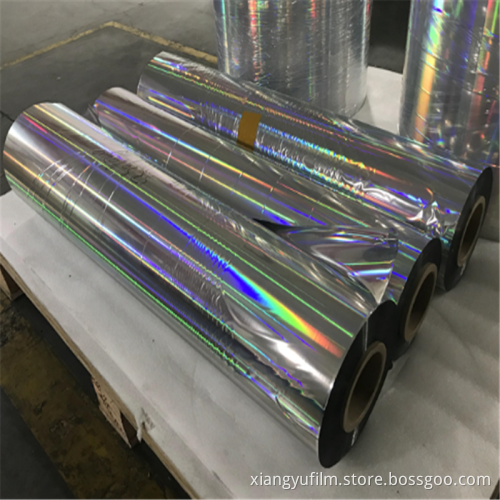

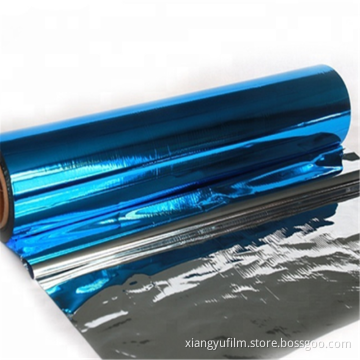

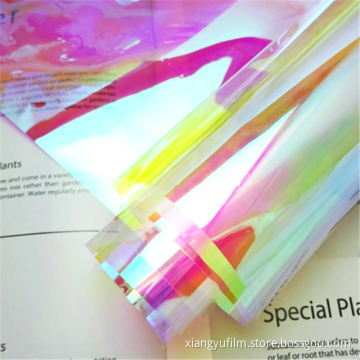

BOPET films have high tensile strength and elasticity modulus. They are non-toxic and odorless. Their surface is glossy and transparent. PET films can resist high impact and withstand both high and low temperatures, exhibit good heat stability. In addition, they are resistant to chemical corrosion and have good water barrier, oxygen barrier, as well as good electrical insulation properties, e.g. high DC breakdown voltage, low dissipation factor and high resistively. Specially treated films are more leveled, have smoother surface, better adhesion and exhibit more dimensional stability,which is an ideal base film for Printing, Lamination, Metallization, Holographic application, Golden & Silver card application, Hot stamping, Transfer-metallization, reflective requirement, Card-lamination, Electrical insulation, Medical Packaging and other applications.

Product Display : Customized Flexbile Packaging Plastic Printing Base Film

Type: LB-xy: un-treated / LBD-xy: single side corona treated.

Thickness: 12~25μm

Application: printing, coating, extrusion coating, heat-sealable pouches, packing materials for food and industrial items.

We Accept Customized.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Performance characteristics:

(1) Good inks, coating layer with good adhesion.

(2) Can be used for multi-color overprint overprint precision.

(3) Good flatness

Typical Properties:

| Project | Unit | Typical values | Test methods |

| Thickness | μm | 12 | DIN 53370 |

| Tensile strength(MD/TD) | MPa | 230/240 | ASTM D 882 |

| Elongation at break(MD/TD) | % | 130/110 | ASTM D 882 |

| Elastic modulus(MD/TD) | MPa | 4400/4600 | ASTM D 882 |

| Heat shrinkage(MD/TD)150℃,30min | % | 1.8/0 | ASTM D 1204 |

| Haze | % | 2.7 | ASTM D 1003 |

Description: MD longitudinal, TD for transverse.

Description above data is only the typical value of the test data, can not be understood as guaranteed values; typical values can be appropriately adjusted according to customer requirements.

Note: MD: Machine Direction; TD: Transverse Direction. The above data can only be regarded as typical physical properties rather than guaranteed values, which can be adjusted at customer’s request.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Strict quality inspection:

To guarantee products quality, our company is equipped with advanced instruments in the quality inspection centre, which includes thickness tester, electron tensile testing machine, heat shrinkage tester, friction coefficient tester, haze and light transmission tester, surface tension tester, deflecting roundel,heat sealing tester,analytical balance, moisture-evaluation analyzer, melting point instrument, ubbelohde viscometer, electro thermal constant- temperature dry box, high temperature furnace and other testing equipments. Every process is strictly inspected from raw material to end products. A combination of sampling and mutual inspection is treated as the principle. The employees from top to bottom are responsible for product quality, ensuring every product is qualified, which is our company’s commitment to every customer.

Related Keywords