High Speed CNC Machine with Ball Screw

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean

- Port:

- Ningbo, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF |

| Transportation: | Ocean |

| Port: | Ningbo,Shanghai |

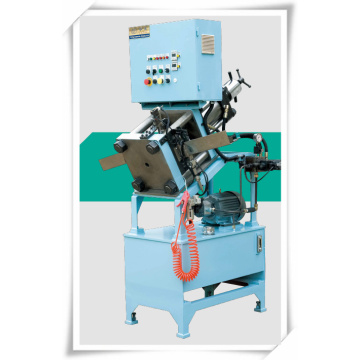

High Speed CNC Machine with Ball Screw

Main features of line rail CNC lathe:

1. The machine tool adopts the trinity of machine, electricity and gas, and is designed according to the ergonomics and humanization. It is fully enclosed and protected, with compact structure, saving area, simple operation and convenient maintenance.

2. The base is of integral high rigid cast iron structure, with smooth chip removal and reasonable cutting space.

3. The line rail has fast moving speed, small rolling resistance, no creeping phenomenon and convenient lubrication. After a long time of use, the accuracy loss is small. Steel inlaid (some pasted plastic) guide rails are often used under heavy load. Especially lubrication is very important to it. When the line rail machining center is processed, the line rail is in rolling friction, point or line contact, with small contact surface and small friction. It is mainly used in high-speed machining and mold industry. For machining with small cutting amount and fast tool walking.

4. High speed angular contact bearing is adopted for the main shaft, and the precision dynamic balance ensures that the main shaft rotates smoothly at high speed and reduces thermal deformation.

5. The longitudinal and transverse movements of the machine tool are directly connected with the lead screw by AC servo motor, and the lead screw bearing is bearing, which ensures the high accuracy of transmission.

6. The machine tool adopts a high-performance automatic intermittent lubrication system, which can timely lubricate the guide rail of the machine body and the X / Z-direction lead screw, ensuring that the guide rail surface and the vertical and horizontal lead screws of the machine tool are always in a good lubrication state.

7. The machine tool adopts row type tool rest, which is convenient for tool arrangement and adjustment. The tool holder is equipped with an automatic material pulling device, which is controlled by the numerical control system and can easily realize online cooperation automation. The tool holder has no fault, which is conducive to improving the production efficiency of the machine tool.

8. The clamping of the workpiece of the line rail CNC lathe adopts the pneumatic clamping of the spring chuck, which is reliable and efficient.

SPECIFICATIONS

BASIC DATA

SF-100

MAX.SWING OVER BED

300mm

MAX.TURNING LENGTH

240mm

X-AXIS TRAVEL(AROSS)

350mm

Z-AXIS TRAVEL(LONGITUDINAL)

240mm

RAPID FEED(X&Z AXIS)

15000mm/min

SPINDLE MOTOR POWER-GSK

4kw

SPINDLE BORE

65mm

MAX.BAR CAPACITY

40mm

SPINDLE SPEED RANGE

50-3000rpm

TOOL SIZE(CROSS SECTIONAL)

20*20mm

POSITIONING UNCERTAINTY(P)

X:0.01mm Z:0.01mm

NET WEIGHT

800KG

GROSS WEIGHT

940KG

SIZE(LENGTH x WIDTH x HEIGHT)

1500mm x1050mm x1700mm

Related Keywords