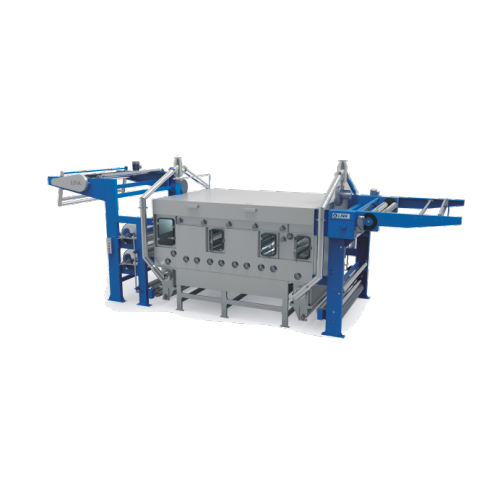

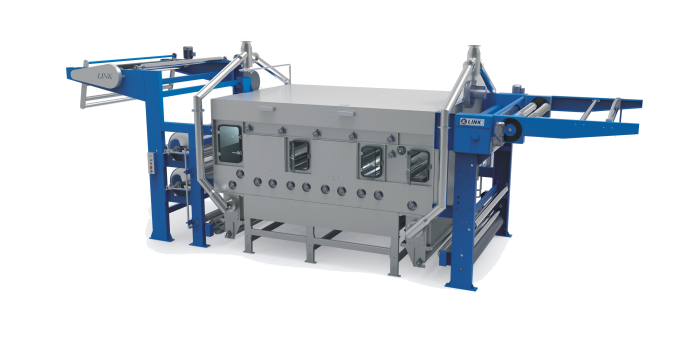

Textile remove crease steam shrink presetting machine

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB, CFR, CIF, EXW, FCA

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 50 Days

- Transportation:

- Ocean

- Port:

- SHANGHAI

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Productivity: | 40set/Year |

| Supply Ability: | 40set/Year |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW,FCA |

| Certificate: | CE, ISO9001: 2000 |

| HS Code: | 8451500000 |

| Transportation: | Ocean |

| Port: | SHANGHAI |

Product Introduction:

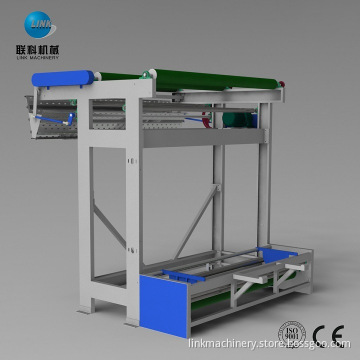

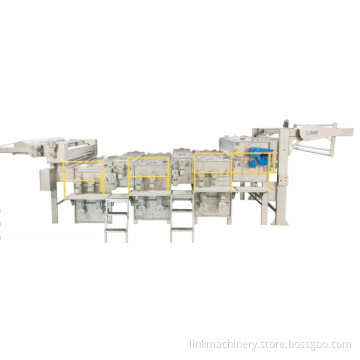

LINK machinery ’s multipurpose steam shrinking machine apply to greige fabric of cotton knit fabric, roma fabric, 4-way stretch fabric, nylon stretch and polyester stretch fabric’s shrinkage and remove crease. It can remove fabric crease effectively, shrink width and release fabric internal stress so that to improve dyeing quality.

Energy Saving Design

01 Both fabric inlet and outlet position is equipped with automatic adjustable double steam sealing structure, without steam leak when heat up, save 30% energy compared with traditional single steam sealing structure.02 The top, two side, before and after of the steam box has heat preservation material, so that reduce steam waste.

Application Range

01 Cotton knit fabric: before greige fabric is presetting by stenter, if fabric is flatted and preshrunk by this machine, weight difference between greige fabric roll head and tail problem will be solved. And fabric crease will be removed so that reduce the problem of weight difference between head and tail and fabric crease problem.

02 Ponte Roma fabric:use wet steaming process, preshrunk & remove crease can improve shrink proportion. Fabric will be more soft after wet steaming finish compared with dry steaming finish and spandex elastic will improve around 15%.

03 Nylon spandex and polyester spandex fabric: Based on high spandex fabric and high shrink requirement fabric, it can remove fabric crease effectively and remedy the less shrink defect by washing machine and reduce the dyed fabric crease problem.

Technological Advantages

01 Can choose saturated dry steam to steaming it or wet steam to steaming it based on different fabric kinds and one key to switch function.

02 Based on knit fabric that’s easy to be edge curl, can use spreading edge device to avoid edge curl. Ponte roma fabric no need to use this spreading edge device.

03 Based on different fabric kind, can use low tension preshrink function to improve shrinkage proportion, or use high tension pull fabric to make it smooth, flexible switch function.

Simple operation

01 The machine use Siemens automation intelligent control system, production state is visual.

02 Touch screen control the whole machine running and one key to finish function switch.03 The machine is equipped with automatic heating control system, automatic tension control device, automatic fill water control device.

|

Model NO. |

LK-PS-2400 |

|

Warranty

|

1 Year |

|

Condition |

New

|

|

Trademark |

LINK |

|

Transport Package |

Wrapped with PE Film+Wooden Pallet

|

|

Specification

|

customized

|

Technical parameter:

Working width: 2200-2600mm

Main voltage: 380V/3PHASES/50HZ

Air pressure: 7bar

Steam pressure: 4bar

Water pressure: 2bar

Operation style: left hand or right hand (optional)

|

Cell No.:0086-15968505600 (SARAH CHEN) ZHEJIANG LINKE MACHINERY CO.,LTD FACTORY & OFFICE ADDR.:NO.318 YUEDONG NORTH ROAD, YUECHENG AREA, SHAOXING, ZHEJIANG, CHINA 312000 Tel:86-0575-85681760 Fax:86-0575-84780306 Web:www.zjlink.com.cn Facebook id: link.machinery |

Related Keywords