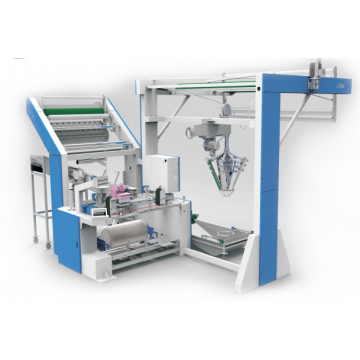

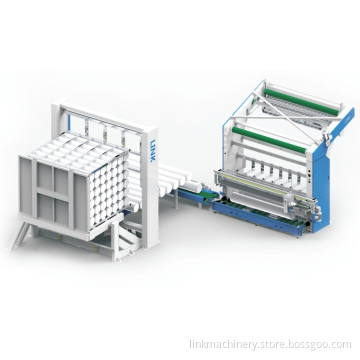

Textile dye continuous souring bleaching washing machine

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB, CFR, CIF, EXW, FCA

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 90 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Productivity: | 40set/Year |

|---|---|

| Supply Ability: | 40set/Year |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW,FCA |

| Certificate: | CE, ISO9001: 2000 |

Product Description

Product Description

Textile Process dyeing Continuous Bleaching Washing Machine

Product Introduction:

Open width continuous bleaching washing machine for cotton knit fabric

This machine apply to dyed fabric's fix color and washing for cotton, rayon and cotton blend knit fabric.

High automation:

01 The whole machine fully automatically control production, include visual running status, can check history production data, alarm production consumables, list machine running error and so on. powerful operation mode.

02 Control system with recipe management system, improved operation simplicity.

03 Touch screen visually show the production output, water and steam consumption, easy to collect and analyse the energy consumption.

04 The machine's central control system is from newest Siemens products, can realize the connection with ERP system and remote to know the machine running data and remote diagnose.

|

Model NO. |

LK-PB-2600 |

|

Warranty

|

1 Year |

|

Condition |

New

|

|

Trademark |

LINK |

|

Transport Package |

Wrapped with PE Film+Wooden Pallet

|

|

Specification

|

customized

|

Recipe management control system:

01 Intelligent recipe control system can work out control data according to production process requirements. There are 0-80 item editable data for each recipe according to different machine. These data include fill chemical, fill water, temperature, pressure, motor drive ratio, tension, flowback or direct drain, PH value, loose or tight fabric pass way switch and so on, to improve the process reproducibility.

02 Operation system can set user grade and operation permissions, easy to operate and manage.

03 System automatically record production running data and can track and check process flow.

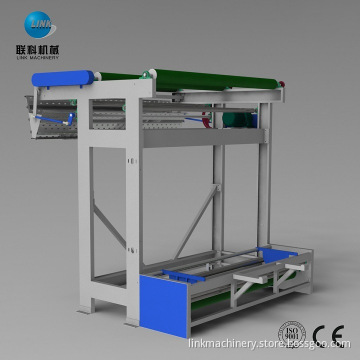

Tension sensor: detect running tension, PLC control the machine synchronously running in low tension according to pre-set tension value.

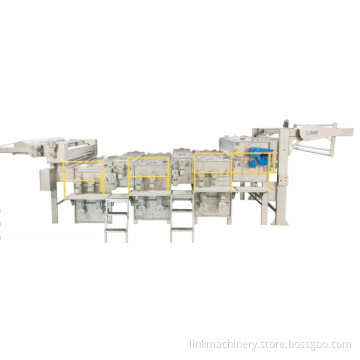

Automatic chemical dosing device: according to pre-set recipe, automatically control dosing, equipped with warning function of lack chemicals.

Rolling bed steamer: fabric move in steamer, to get better even reaction between chemical and fabric.

Heat exchanger: fabric pre-heat the feeding water to make sure the even temperature of each chamber.

Dwell washing chamber: Can choose dwell neutralize wash or dwell fix color wash according to different recipe setting. One key to switch tight fabric pass way.

Proportional valve: flowmeter automatically control water inflow of each chamber according to recipe setting.

Technical parameter:

Working width: 2200-2600mm

Main voltage: 380V/3PHASES/50HZ

Air pressure: 7bar

Steam pressure: 4bar

Water pressure: 2bar

Operation style: left hand or right hand (optional)

|

Cell No.:0086-15968505600 (SARAH CHEN) ZHEJIANG LINKE MACHINERY CO.,LTD FACTORY & OFFICE ADDR.:NO.318 YUEDONG NORTH ROAD, YUECHENG AREA, SHAOXING, ZHEJIANG, CHINA 312000 Tel:86-0575-85681760 Fax:86-0575-84780306 Web:www.zjlink.com.cn Facebook id: link.machinery |

Textile Process dyeing Continuous Bleaching Washing Machine

Product Introduction:

Open width continuous bleaching washing machine for cotton knit fabric

This machine apply to dyed fabric's fix color and washing for cotton, rayon and cotton blend knit fabric.

High automation:

01 The whole machine fully automatically control production, include visual running status, can check history production data, alarm production consumables, list machine running error and so on. powerful operation mode.

02 Control system with recipe management system, improved operation simplicity.

03 Touch screen visually show the production output, water and steam consumption, easy to collect and analyse the energy consumption.

04 The machine's central control system is from newest Siemens products, can realize the connection with ERP system and remote to know the machine running data and remote diagnose.

Recipe management control system:

01 Intelligent recipe control system can work out control data according to production process requirements. There are 0-80 item editable data for each recipe according to different machine. These data include fill chemical, fill water, temperature, pressure, motor drive ratio, tension, flowback or direct drain, PH value, loose or tight fabric pass way switch and so on, to improve the process reproducibility.

02 Operation system can set user grade and operation permissions, easy to operate and manage.

03 System automatically record production running data and can track and check process flow.

Tension sensor: detect running tension, PLC control the machine synchronously running in low tension according to pre-set tension value.

Automatic chemical dosing device: according to pre-set recipe, automatically control dosing, equipped with warning function of lack chemicals.

Rolling bed steamer: fabric move in steamer, to get better even reaction between chemical and fabric.

Heat exchanger: fabric pre-heat the feeding water to make sure the even temperature of each chamber.

Dwell washing chamber: Can choose dwell neutralize wash or dwell fix color wash according to different recipe setting. One key to switch tight fabric pass way.

Proportional valve: flowmeter automatically control water inflow of each chamber according to recipe setting.

Technical parameter:

Working width: 2200-2600mm

Main voltage: 380V/3PHASES/50HZ

Air pressure: 7bar

Steam pressure: 4bar

Water pressure: 2bar

Operation style: left hand or right hand (optional)

|

Cell No.:0086-15968505600 (SARAH CHEN) ZHEJIANG LINKE MACHINERY CO.,LTD FACTORY & OFFICE ADDR.:NO.318 YUEDONG NORTH ROAD, YUECHENG AREA, SHAOXING, ZHEJIANG, CHINA 312000 Tel:86-0575-85681760 Fax:86-0575-84780306 Web:www.zjlink.com.cn Facebook id: link.machinery |

Related Keywords

Related Keywords