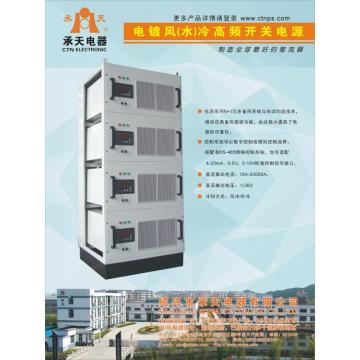

Iron Plat SCR Power Supply

- Payment Type:

- T/T

- Incoterm:

- FOB, CIF

- Min. Order:

- 1 Bag/Bags

- Min. Order:

- 1 Bag/Bags

- Delivery Time:

- 35 Days

- Transportation:

- Ocean

- Port:

- Ningbopare

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | shaoxing |

|---|---|

| Productivity: | 99999PS |

| Payment Type: | T/T |

| Incoterm: | FOB,CIF |

| Certificate: | CE |

| HS Code: | 8543300090 |

| Transportation: | Ocean |

| Port: | Ningbopare |

Product Description

Product Description

I. Purpose and Model Meaning:

iron plating power source is designed specifically for ferrous chloride, ferrous salt or fluoboric acid sulfate salt plating iron electroplating and other requirements and design. The power supply is widely used to repair the shaft, cylinder liner and other parts due to corrosion and wear. It can also be used to replace hard chrome plating with iron plating to improve the wear resistance of the plated parts and prolong the service life.

type:

S K DT F A/ V

Output rated DC voltage

Output rated DC current

Cooling mode code

Iron plated power supply code

Device type code

AC/DC asymmetry code

Cooling mode code: A -- self cooling F -- air cooling J -- oil cooling

Use code: DT - iron plating

Device type code: K -- thyristor voltage regulation

II. Technical parameters and characteristics:

1. Adopted standards:

Enterprise standard Q/SCD 001-2000 "silicon, silicon controlled rectifier standard"

2. Main technical parameters:

rated output voltage: V.

rated output current: A;

input power: 380 + / - 10%, 50 to 60 hz;

stable voltage, stable current accuracy of + / - 1%;

soft start time adjustable 0-180 seconds;

oad rating for the "I", that is, 100% rated peak current work continuously.

3. Product features:

① It has the function of automatic voltage stabilizing and current limiting.

Voltage stabilizing and current limiting function: when the rectifier works in this state, if the load changes, the voltage will be stable and the current will change with the load. When the current reaches or will exceed the rated peak current, it will automatically be in the current limiting state, that is, the maximum current does not exceed the rated peak current, and the voltage will drop.

② It has high and reliable over-current and short-circuit protection function.

When the load current exceeds 50% of the rated value, the rectifier will automatically block the output pulse, the operation time is 10ms, and it will be maintained until the shutdown.

③ It has the function of phase error protection

When the three-phase power line appears out of phase, the rectifier will automatically block the output pulse, then the buzzer HA rings, which indicates that the phase sequence is wrong, then just change the phase sequence of the power supply line.

(4) AC/DC asymmetrical working waveform

In general, the output waveform is shown in the figure below.

OA is a positive half wave, AB is a negative half wave, Oc is the transition iron plating stage (the stage is about 20min),C is the DC plating stage. The ratio of positive and negative half wave current density (β) can be adjusted uniformly from 1 to 10 during the transition iron plating stage.

⑤ The main transformer adopts two vacuum dipping or hot dipping and drying.

The three-phase integrated trigger control board has multiple protective measures, is a novel high threshold anti-interference strong integrated double pulse trigger circuit, advanced performance, good output waveform, reliable operation, convenient debugging.

With soft start function, prevent large current impact, to ensure the quality of the coating.

The use of computer standardized design, box spraying, both anticorrosive and beautiful.

iron plating power source is designed specifically for ferrous chloride, ferrous salt or fluoboric acid sulfate salt plating iron electroplating and other requirements and design. The power supply is widely used to repair the shaft, cylinder liner and other parts due to corrosion and wear. It can also be used to replace hard chrome plating with iron plating to improve the wear resistance of the plated parts and prolong the service life.

type:

S K DT F A/ V

Output rated DC voltage

Output rated DC current

Cooling mode code

Iron plated power supply code

Device type code

AC/DC asymmetry code

Cooling mode code: A -- self cooling F -- air cooling J -- oil cooling

Use code: DT - iron plating

Device type code: K -- thyristor voltage regulation

II. Technical parameters and characteristics:

1. Adopted standards:

Enterprise standard Q/SCD 001-2000 "silicon, silicon controlled rectifier standard"

2. Main technical parameters:

rated output voltage: V.

rated output current: A;

input power: 380 + / - 10%, 50 to 60 hz;

stable voltage, stable current accuracy of + / - 1%;

soft start time adjustable 0-180 seconds;

oad rating for the "I", that is, 100% rated peak current work continuously.

3. Product features:

① It has the function of automatic voltage stabilizing and current limiting.

Voltage stabilizing and current limiting function: when the rectifier works in this state, if the load changes, the voltage will be stable and the current will change with the load. When the current reaches or will exceed the rated peak current, it will automatically be in the current limiting state, that is, the maximum current does not exceed the rated peak current, and the voltage will drop.

② It has high and reliable over-current and short-circuit protection function.

When the load current exceeds 50% of the rated value, the rectifier will automatically block the output pulse, the operation time is 10ms, and it will be maintained until the shutdown.

③ It has the function of phase error protection

When the three-phase power line appears out of phase, the rectifier will automatically block the output pulse, then the buzzer HA rings, which indicates that the phase sequence is wrong, then just change the phase sequence of the power supply line.

(4) AC/DC asymmetrical working waveform

In general, the output waveform is shown in the figure below.

OA is a positive half wave, AB is a negative half wave, Oc is the transition iron plating stage (the stage is about 20min),C is the DC plating stage. The ratio of positive and negative half wave current density (β) can be adjusted uniformly from 1 to 10 during the transition iron plating stage.

⑤ The main transformer adopts two vacuum dipping or hot dipping and drying.

The three-phase integrated trigger control board has multiple protective measures, is a novel high threshold anti-interference strong integrated double pulse trigger circuit, advanced performance, good output waveform, reliable operation, convenient debugging.

With soft start function, prevent large current impact, to ensure the quality of the coating.

The use of computer standardized design, box spraying, both anticorrosive and beautiful.

Related Keywords

Related Keywords